Last Updated on September 30, 2022 by admin

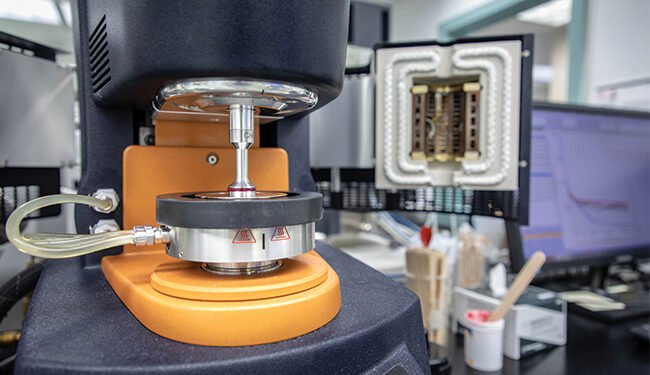

Rheometer

A rheometer is a laboratory device used for measuring the flow of fluids of different viscosities. This type of instrument requires more variables to measure than a viscometer. In general, a rheometer is more expensive than a viscometer. Here are some considerations when purchasing a rheometer. Buying one should be an easy process and can help you get the results you need.

Working principle

A rheometer is a device that uses the force of friction to determine the resistance to flow in a fluid. There are several types, including the Weissenberg Rheogoniometer. Weissenberg rheometers are absolute instruments, and require careful calibration to achieve a precise reading. Other instruments on the same principle can be simpler to use, but may require calibration with a known fluid.

Capillary rheometers use a vertically mounted, heated barrel with a capillary die that has a known L/D ratio. Then, a piston is driven into the barrel at a constant speed. The result is a pressure drop that stabilizes at a preset point. The process is repeated until the desired value is reached. The resulting pressure value is then measured.

Range of measurement

A rheometer is an instrument used to measure the rheological properties of materials. They can be used to study fluids, concentrated protein formulations, semisolids, and solid polymers. The rheological properties of materials can impact the formulation development process. The range of measurement for a rheometer depends on the type of sample being measured as well as the viscosity.

A rheometer comes in two basic types: a capillary rheometer and a torque meter. The former is used to measure true viscosity, while the latter is used to measure relative viscosity by torque correlation. The capillary rheometer is the preferred type of rheometer for compounders, while the latter is better for troubleshooting flow in injection molds and dies. A torque rheometer is also used for mixing batches of materials to test their flowability.

Cost

A rheometer is a tool used to measure viscoelastic properties of materials. Depending on the application, it can measure the extensional viscosity, melt strength, or tensile strength. One of the more expensive models is the Goettfert Rheotens, which costs more than $60,000, and can be used to test the elasticity of rubber, plastic, or film. Other suppliers of rheometers have developed different methods of measurement, including software correlations and special hardware accessories.

A twin-bore capillary rheometer costs around $50,000. It saves you time by allowing you to obtain two measurements during a single test cycle. It also calculates Bagley corrections automatically, resulting in a more accurate measure of absolute viscosity. These machines use two dies with the same diameter but different lengths, and produce different shear stresses, which allows for more accurate measurement.

Problems with some rheometers

A rheometer is a device used to measure the flow of a dense fluid. Its measurement of the rheology of the fluid can help to determine whether a particular formulation is sensitive to degradation. Some rheometers suffer from problems, including inertia, which is a large amount of resistance compared to the resistance provided by the material. This article discusses the major problems associated with rheometers and how to address them.

The most important properties of a rheometer are its ability to measure the shear stress and the shear rate of a fluid. Different types of instruments are designed to measure these properties. They have different advantages and disadvantages. This article will provide answers to some of the most common questions associated with rheometers. There are two basic types of rheometers: rotational rheometers and shear rheometers. Rotational rheometers are more widely used. They are easier to use, and are often less expensive.

Cost of a rheometer

There are many different types of rheometers, and some are more expensive than others. Commercial rheometers rely on expensive force transducers to measure the torque associated with a sample strain. These units can cost upwards of $40000. Alternatively, you can build a portal rheometer yourself for as little as $400. These are practical for educational and field use. Here are a few things to consider when purchasing a rheometer.

First, consider the type of test you need to do. Most viscometers are designed for measurements of a single point on the shear-rate-viscosity curve, providing a crude indicator of flowability. In contrast, rheometers measure multiple points on the curve, and are often more accurate in determining the flow characteristics of materials. Whether your lab is measuring viscosity of liquids, emulsions, or other materials, you should choose a rheometer that measures the range of shear rates and stresses.